Manufacturing

AI helps manufacturers run smarter operations, reduce downtime and deliver consistent quality. The result is higher throughput, lower cost per unit and faster response to demand.

How we apply AI in your industry

These examples are just a glimpse of what’s possible — every solution is tailored to your business needs.

Machine Learning

Manufacturing generates rich process, sensor and quality data. Machine learning turns those signals into early warnings and optimisation insights that lift yield and protect margins.

Predictive maintenance and remaining useful life

Detect wear early and estimate how long assets can run safely to cut unplanned downtime and maintenance cost.

Product defect detection

Spot defects with computer vision and sensor patterns to improve first-pass yield and reduce rework.

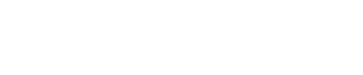

Dynamic optimisation of machine parameters

Tune setpoints in real time to stabilise processes and maximise throughput without sacrificing quality.

Process scheduling and digital twin simulation

Simulate and optimize production schedules before deployment to shorten cycle times and increase line utilisation.

Logistics routing and stock movement optimisation

Shorten lead times, cut kilometres travelled and lower transport cost.

Autonomous machines

Use vision and sensors to automate guided movements and handling tasks that improve safety and consistency.

Process automation

Orchestrate work orders, approvals and data entry across ERP, MES and QA systems to reduce delays and errors.

Adaptive production systems

Let lines self-adjust to input variability and small disturbances to keep output on target.

Generative design for production lines

Explore layout and tooling options under real constraints to reach better designs faster.

Product support and recommendation agents

Provide technicians and customers with instant troubleshooting and parts guidance to shorten resolution times.

Automation

Automation connects machines, lines and back-office systems so routine work runs reliably. Teams spend less time on handoffs and more time improving performance.

Intelligent Document Processing

Factories run on specifications, reports and certificates. IDP converts unstructured documents into clean data that flows into quality, compliance and planning.

Quality and compliance report processing

Extract and validate key fields from QA reports and certificates to speed audits and ensure conformance.

Document-to-structured-data conversion

Turn PDFs, emails and scans into structured records that fill the correct fields in your ERP, CRM or database, eliminating manual entries.

Media-signal demand prediction

Analyse public media and marketing signals to improve short-term demand forecasts for planning and procurement.

Related Case Studies

These are just a few examples of how AI can transform your business. Every operation has unique challenges — let’s explore what’s possible for yours.