Overview

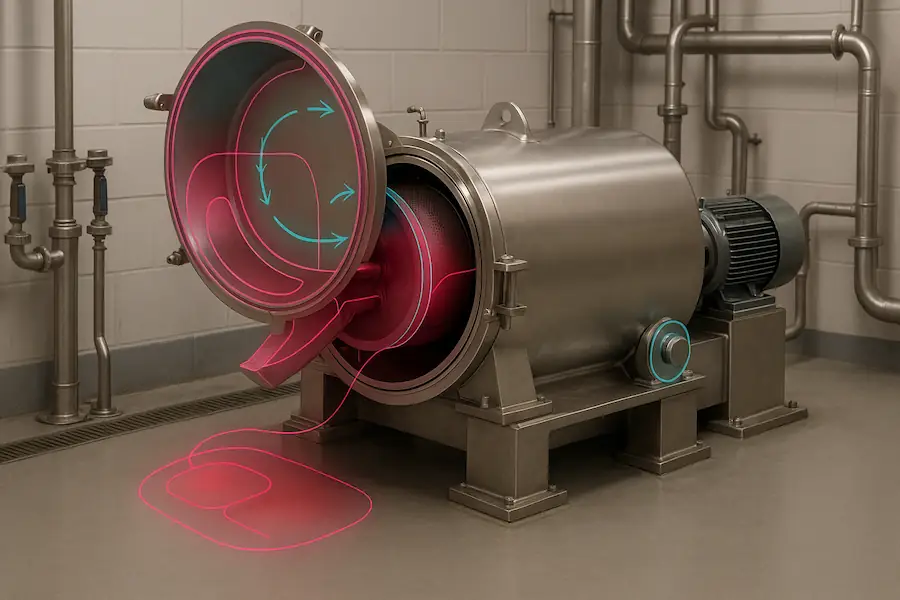

We worked with Wesfarmers Chemicals, Energy & Fertilisers to predict upcoming centrifuge vibration levels using a machine learning model trained on historical sensor data, enabling timely washes and reducing wear.

Problem

Material build-up on centrifuge walls increases vibration and accelerates equipment wear. Scheduled periodic washes could not always occur in time to prevent prolonged high vibration, and were wasteful when no spike was imminent.

Solution

- Predictive model: Trained on historical data from several centrifuges to forecast near-term vibration levels.

- Actionable timing: Designed to trigger targeted washes and maintenance when risk is rising, and avoid unnecessary cleans when it is not.

Result

- Early warning: Predicted when centrifuges would consistently exceed safe vibration levels up to 1 hour in advance, with over 90% accuracy.

- Operational gains: Significant reduction in production downtime and water usage from unnecessary washes.