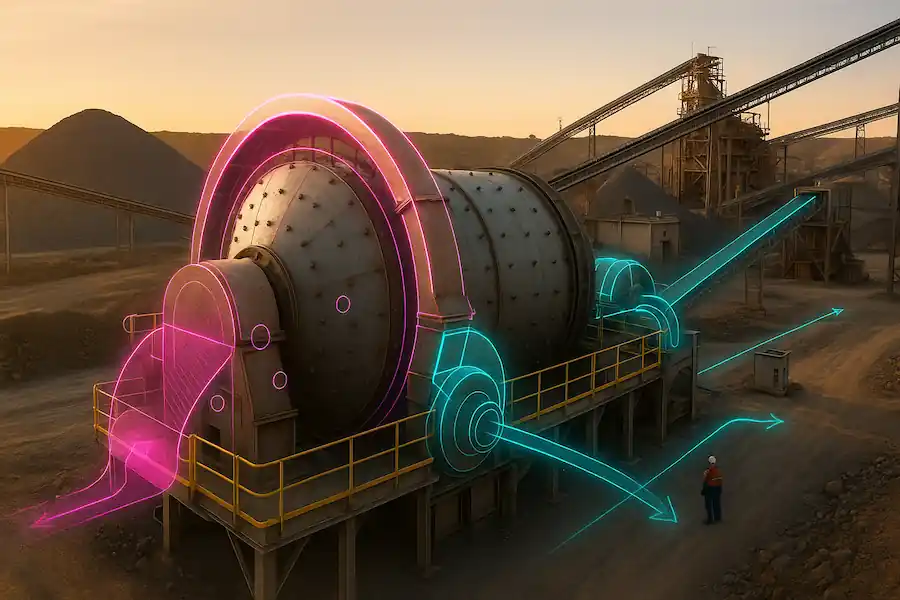

Overview

We worked with HiSeis to automate first-break picking using deep learning that detects refracted wavelets across millions of geophone traces, achieving accuracy within 4 milliseconds of an expert.

Problem

Manual first-break picking is slow and error-prone in noisy data. Existing tools and published techniques at the time were not accurate enough for HiSeis to reliably identify wavelets refracting from different rock formations.

Solution

- Deep-learning approach: Applied computer-vision techniques to learn patterns in audio-vibration and geophone sensor data to predict target wavelets among large volumes of traces.

- Expert-grade accuracy: September AI’s method performed within a 4 millisecond error of an expert technician and, in many cases, outperformed the human.

Result

- Significantly improved accuracy and consistency than manual picking.

- Efficiency gains that reduce time and cost associated with manual first-break picking.