Overview

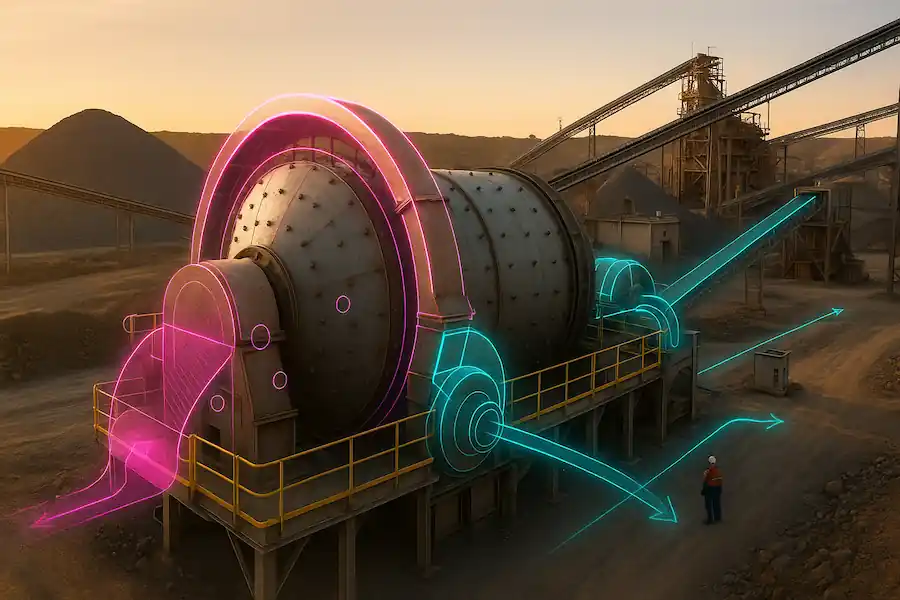

We helped BHP to improve Semi-autogenous grinding (SAG) mill throughput by deploying a machine learning model that ingests real-time, site-specific data across drilling, blasting, crushing, and SAG operations. Its explainable machine learning outputs show which factors drive each prediction, so operators can trust and act on recommended set-points.

Problem

Physics-based and commercial simulation tools were not accurate enough for real-time control. Just as importantly, they lacked explainability — operators couldn’t see which inputs influenced predictions, making it hard to adjust set-points with confidence.

Solution

- Integrated ML model: Uses live plant data from drilling, blasting, crushing, and SAG mill operations to estimate throughput and recommend set-points (e.g., crusher gap settings, SAG mill speed, percentage of solids) for the current operating context and constraints.

- Explainable outputs: The model’s inbuilt explanatory power highlights the features influencing each prediction, helping operators understand why recommendations are made and increasing adoption in live plant operations.

Result

- Prediction uplift: 42% better than the existing physics-based model and 27% better than commercial simulation software on average.

- Throughput gain: Applying the optimal set-points increased throughput by 12% on average.

- Operator confidence: Clear explanations supported decision-making in live operations.